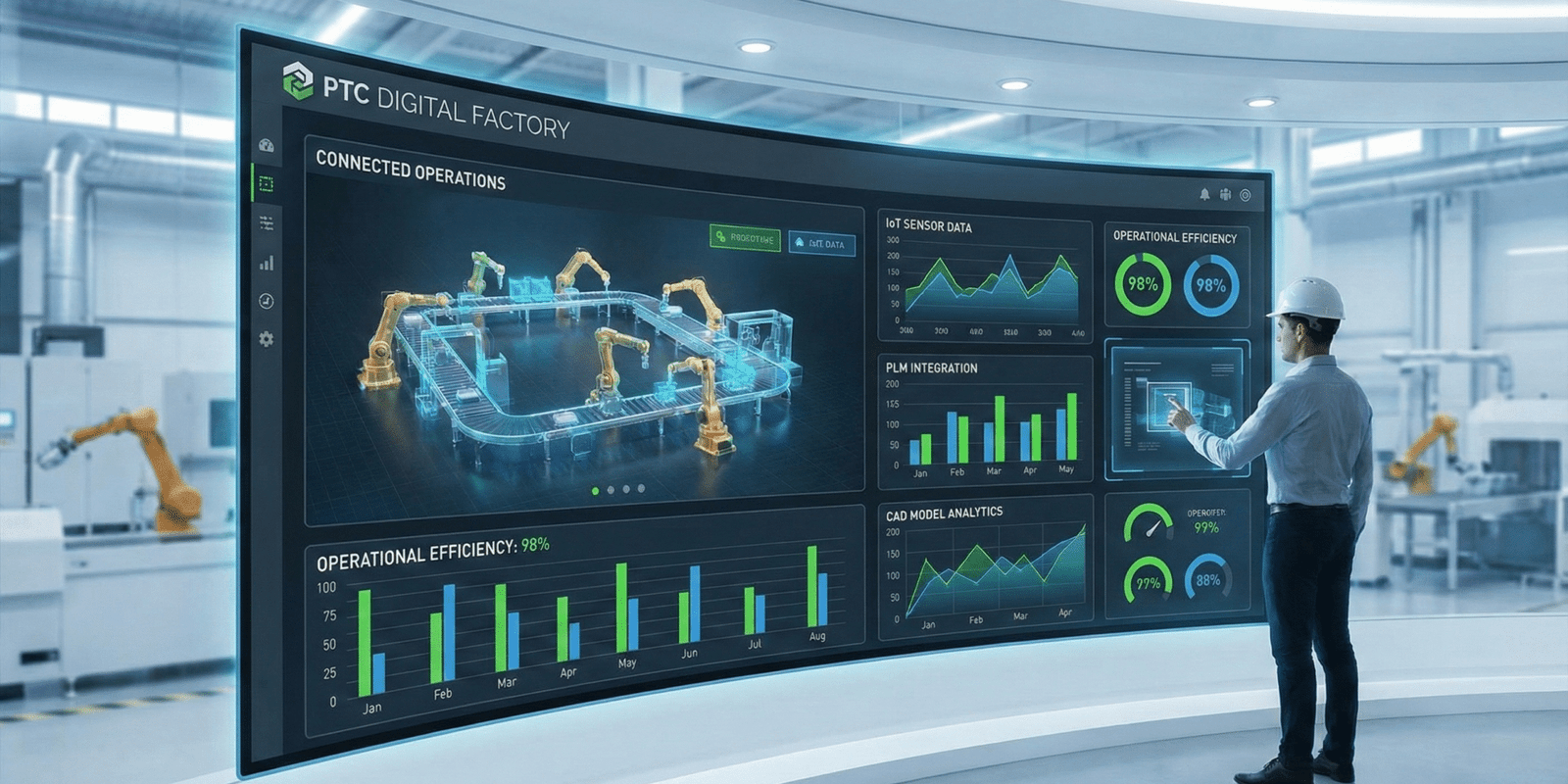

In today’s rapidly evolving industrial landscape, companies are increasingly turning to PTC digital transformation solutions to modernize operations, enhance productivity, and remain competitive. From connected devices to advanced software tools, PTC empowers manufacturers to integrate data, streamline workflows, and embrace Industry 4.0 technologies seamlessly.

Whether a factory is implementing IoT-enabled monitoring or leveraging CAD and PLM systems for product design, PTC’s solutions ensure teams can collaborate efficiently, reduce errors, and make data-driven decisions.

Seamless Integration of IoT and Industrial Software

PTC is well-known for its IoT platform, ThingWorx, which connects machines, sensors, and software applications in real time. By combining IoT data with manufacturing operations:

- Predictive maintenance becomes possible, reducing downtime.

- Operational efficiency improves through real-time monitoring.

- Analytics dashboards provide actionable insights to optimize production.

These tools allow companies to detect potential bottlenecks before they impact operations, ensuring smoother workflows and higher output.

Advanced CAD and PLM Solutions

Design and product lifecycle management are critical components of modern manufacturing. PTC offers:

- Creo CAD tools: For accurate 3D design and rapid prototyping

- Windchill PLM: To manage the product lifecycle from conception to retirement

With PTC digital transformation, engineers and product teams can collaborate virtually across locations, share designs instantly, and accelerate innovation cycles without compromising quality or compliance.

Driving Efficiency Through Cloud-Based Solutions

PTC’s cloud offerings enable manufacturers to unify processes, data, and teams in a centralized platform. Benefits include:

- Scalable infrastructure to support global operations

- Secure data storage and controlled access

- Flexible deployment to match organizational needs

Cloud integration ensures that manufacturers, suppliers, and partners can access critical information anytime, anywhere, leading to faster decision-making and better resource allocation.

Real-Life Applications of PTC Digital Transformation

1. Predictive Maintenance in Automotive Manufacturing

A major automotive manufacturer implemented PTC’s ThingWorx platform to monitor equipment in real-time. Within months, unplanned downtime decreased by 25%, saving significant maintenance costs.

2. Accelerated Product Design for Consumer Electronics

A global electronics firm used Creo CAD tools and Windchill PLM to manage multiple design iterations across international teams. Product development cycles shortened by 20%, and collaboration improved significantly.

3. Smart Factories and Connected Workflows

PTC’s digital solutions enable smart factories where data from machines, sensors, and enterprise systems converge. Managers can track KPIs instantly and respond proactively to production challenges, improving overall operational efficiency.

Key Benefits of PTC Digital Transformation

- Enhanced Collaboration – Teams across geographies can work together seamlessly.

- Data-Driven Insights – Real-time analytics inform better operational decisions.

- Reduced Errors and Downtime – Predictive maintenance and centralized workflows prevent costly mistakes.

- Scalability – Solutions grow with the business, supporting global operations.

- Innovation Enablement – Faster prototyping and iteration accelerate product development.

Tips for Adopting PTC Solutions

- Start with key processes: Identify operations that will benefit most from digitalization.

- Train employees: Ensure teams understand platform capabilities and workflows.

- Integrate IoT and PLM: Connect devices and data with design and production systems.

- Monitor KPIs continuously: Use dashboards to track efficiency and adoption.

- Collaborate with experts: Leverage PTC’s consulting services for smooth deployment.

Conclusion

PTC digital transformation empowers manufacturers to embrace the future of Industry 4.0. By combining IoT, cloud solutions, CAD, and PLM platforms, companies can reduce downtime, streamline workflows, and innovate faster. Businesses that adopt PTC’s solutions not only enhance operational efficiency but also create a competitive edge in a market where speed, precision, and adaptability determine success. In an era defined by digital transformation, PTC provides the tools, insights, and support to ensure manufacturing operations are smarter, safer, and more connected than ever.

Read Our Recent Blog On Google’s $15B AI Hub investment in India

This was beautiful Admin. Thank you for your reflections.